Monday, 18 November 2024

The Innocent Railway

I haven't posted a video here for a while, but within the research being carried out for a future project, this popped up. Simple enough fare, but oozing with atmosphere and just a bundle of modelling inspiration and detail.

Drovers Brook taking shape

I'm hitting the cardboard now with the bridge all but done and most of the structures at least part built. So far I'm quite pleased with the feel of it. This doesn't bode well as this is usually the juncture at which I start to doubt if I like it or not.

Thursday, 14 November 2024

Shattered

Tuesday, 12 November 2024

Little things

I doubt that I am alone in suddenly having a workbench full of 'I'll do that in a minute' things. The odd repairs and bits of painting that won't actually take long, but interrupt the flow of the more important task at hand.

With the brake van winging its way toward landfill and the condemned 16 tonners into the Rhiw 2 stock box, things turned back to Drovers Brook. One of the workbench things that were hanging around were these two sets of stop blocks - one old school Peco for the Code 75 track at the platform release end and the newer Bullhead item which is for the coal siding. They are noticeably different, but are not interchangeable across the rail types. Painted with first 62 orange as a base and then Typus Corrosion and a wash of black. I note with some amusement that this had essentially taken three coats of paint to get them to the colour that that started out at. Hmmmm.... though there is a much more matt texture. Only one lamp needed and this and the wood blocks were touched in with brown, white and SR brown for the lens; not red. These and tie-bars repaired on Rhiw's runner wagon has dented the pile somewhat.

Saturday, 9 November 2024

Airfix/Dapol brake van 3/ramble

The inner ends. Oh dear, getting worse by the minute. The door is a separate piece and was like a surfboard. I filed the back flat so that it would sit into the recess. The witness marks are another thing altogether. Why? Just why? Why on the outside? There are faint plank marks and the handrails also on the face, so any sanding would remove these. Frankly this a complete dog's dinner and I can't see that this would be more acceptable in the late 60s than it is now.

At this point I took a long hard look at it, calculated the forward time to spend both finishing and correcting it. I decided that this was not worth the effort and abandoned the project. Sometimes it's better to walk away.

Thoughts: Some of the Dapol reissues work; the building kits are OK with the usual caveats. Here though it gets embarrassing. Say you were a new modeller and you hand over nine quid in Gaugemaster for one of these. This is, or should be, entry level stuff; Saturday afternoon kit building. It's a full ten star fail and thus tars every other plastic wagon kit with the same brush before the ponies are out of the gates. I've had half a century of kit building and I can't make this work without some major non-cost-effective butchery. Detailing a Tri-ang would be a better start point.

Thursday, 7 November 2024

Airfix brake 2

It was was some trepidation that work began. I settled myself with the attitude that this was pence spent so no problem if it were to be abandoned halfway through and jumped on; or recycled back into Coke bottles.

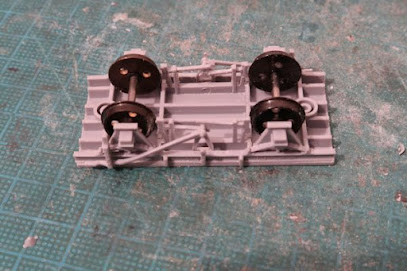

The floor was raised at one end by 2-3mm. I bent this back as best I could. I'm not a lover of under-floor ribbing on kits, but in this case it looked like I needed it. One end was welded to the bent end and then I worked my way along and plonked a 3K weight on it while it hardened.

Satisfied with this I moved onto the solebars. As with the 16 tonner 2mm holes were drilled and bearings added. Did I mention that if they were thrown that they would probably come back? I fear this will be a recurring theme to the build. Again one end welded, and as per the floor sans weight. You can clearly see the 2mm differential at the RH end pre-sticking.A long time ago I built (or didn't) a kit of the QE2. The hull sides were 1/4" different in length. So it was here with sole bars. One was fixed and the second waggled around until I got the axles almost parallel. It runs... but won't win any prizes. So far, so... well just so far really.

Wednesday, 6 November 2024

Airfix brake van

Oh yes, there's more! On a roll and once more into the box. Well I may as well do the whole train now I'm 75% there. This is a mixed bag, and this is what I have. As per usual it came off a club stand at not much money. There are risks involved here, but then that can be half the fun. Pluses are that the seller (and I know who) included a set of Romford wheels. The downsides are 1. It's Dapol made and 2.as far as I can ascertain at first sift through, there is a set of foot steps that have put the best foot forward and walked off.

Tuesday, 5 November 2024

Airfix mineral wagon final

And so to paint. The whole lot was given a coat of Humbrol 62 orange as a base. Then, slightly paler than normal, the body outer, a coat of Citadel Corax White. Photos of 16 tonners often show an almost white finish, so I could dare to be pale.

Transfers were added from the ModelMaster range and varnish applied. The the underframe was hit with Citadel Charonden Granite (sadly no longer available). Then with a cut down old brush I dabbed around with Typhus Corrosion, followed by more 62 over the top, applied in both thin and gloopy form.

The final wash of Humbrol 33, to suggest a thin layer of coal dust, was applied with the wagon held upside down and then some wagon works gothic 6" brush lettering.

There is a lot wrong with the Airfix 16 tonner, but considering its age it's still workable into something fun and acceptable. All for two bob.

Monday, 4 November 2024

It's nice to go travelling

Once in a while this decade-old post rolls up in the viewer stats and for once is quite timely. In other words I may actually do something about it. There is much to work out and even more that could go wrong to kybosh the idea, however, travelling hopefully... like an elderly gentleman I suppose.

Sunday, 3 November 2024

Airfix Mineral wagon 4

The body parts are assembled in pairs trying to remember that they are handed. Yes I've done it. We've all done it.

The body dropped on and fixed, and two pieces of lead sheet dropped onto a puddle of UHU. Once the inside is painted these disappear in the grime from normal viewing angles.

Friday, 1 November 2024

Airfix Mineral wagon 3

Support the blog here: